Selecting just the right power cord or cord set for your electrical design is a critical step. Especially if your product will be used worldwide. Electrical terminology can be confusing when people use multiple terminology when referring to one product: words that describe connecting electrical equipment to a power source may be referred to as a detachable or non-detachable cord, an appliance cord, a cable, a cable assembly, an interconnection, or a power supply—and, a power cord, cord set, jumper cord, or a connector power cord.

Selecting just the right power cord or cord set for your electrical design is a critical step. Especially if your product will be used worldwide. Electrical terminology can be confusing when people use multiple terminology when referring to one product: words that describe connecting electrical equipment to a power source may be referred to as a detachable or non-detachable cord, an appliance cord, a cable, a cable assembly, an interconnection, or a power supply—and, a power cord, cord set, jumper cord, or a connector power cord.

For the purpose of clarity, Interpower uses the following terms: power cord, jumper power cord, connector power cord, cord set, and jumper cord set.

Choosing a Cord/Cord Set Usually Involves Four Steps:

- Identify the Correct Plug According to Where the End User Will be Located

Determining the correct plug is essential. Interpower offers a Guide to Worldwide Plug and Socket Patterns and Power Mains (Single-Phase) which provides frequently specified plug patterns by country. “When deciding on the correct plug pattern, keep in mind that while some plugs may look similar, it doesn’t mean it’s the right plug for the product. For example, the plugs used in Argentina, Australia, and China have similarities in appearance, but have crucial differences between them and cannot be used interchangeably within those countries,” said Ron Barnett, Product Development Manager at Interpower.

- Determine the Rating of the Power Cord or Cord Set

It is important to know the amperage and voltage ratings required for the exported project. “Higher or lower amperage can mean a different plug pattern, even in the same country,” Barnett said. “Amperage requirements affect the cable size. North America uses a different voltage, amperage, and frequency compared with most other countries.” The Guide to Worldwide Plug and Socket Patterns and Power Mains (Single-Phase) provides information on voltage and frequency requirements.

- Choose the Correct Cable

North American cable is different from international cable, which in turn is different from Japanese or Chinese cable. “For example,” Barnett said, “North American cable cannot be used in countries where international cable standards are in place and vice versa. In other words, removing a North American plug from a cord set made with North American cable and replacing it with a Continental European plug will not make the cord set acceptable for Europe.”

- Choosing the Correct Connector When Utilizing a Cord Set

If exporting globally, consider incorporating IEC 60320 components into the product design. “The advantage of using an IEC 60320 component is that it can assist in making the product globally accessible,” Barnett said. “For example, an IEC 60320 connector can be attached to a detachable cord set with a country-specific plug. The connector will provide the power to the equipment by connecting with an IEC 60320 inlet in the equipment. The use of IEC 60320 components designed into a product allows the same equipment to be used in a variety of markets which use North American or International voltages.”

An important note regarding the rating on the power cord or cord set: A cord set is rated by its “lowest” rating. For example, a cord set with a 15A plug on 13A cable with a 10A connector will have an overall rating of 10A.

Guidelines

Interpower manufactures a number of power cords and cord sets according to the following guidelines:

- All appropriate standards are followed.

- Minimum and maximum lengths are followed for country-specific standards.

- Current ratings are based on the lowest-rated component.

- Voltage ratings are based on the lowest-rated component.

Power Cords

Power Cords

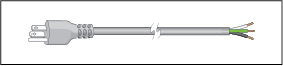

A power cord consists of cable with a country-specific plug (molded or hand wired) on one end and exposed conductor wires, terminated conductors, or blunt/flush cut conductors on the other end. A power cord is used to connect the equipment directly to the power mains.

Jumper Power Cord (or Accessory Power Cord)

A jumper power cord is made from cable and an IEC 60320 Sheet E or Sheet I plug connector (molded or hand wired) on one end. A jumper power cord is used to connect a secondary piece of equipment (accessory) to a primary piece of equipment which is supplying the power to the peripherals.

Connector Power Cord

A connector power cord has an IEC 60320 or country-specific connector (molded or hand-wired) on one end of the cable with the opposite end being exposed conductor wires, terminated conductors, or blunt/flush conductors.

Cord Sets

Cord Sets

A cord set consists of cable with a country-specific plug (molded or hand wired) on one end and an IEC 60320 connector or country-specific connector (molded or hand wired) on the other end. It is meant for connecting equipment directly to the mains supply.

Jumper Cord Set (or Accessory Cord Set)

A jumper cord set works like a jumper power cord. The difference is a connection device on both ends of the cable instead of just the plug end. A jumper cord set includes an IEC 60320 plug connector and an IEC 60320 connector and transfers power from a primary piece of equipment to an accessory or peripheral piece of equipment.

Cable length is a choice for the manufacturer, depending upon the application. “Interpower offers standard length power cords and cord sets as well as custom lengths. When manufacturing power cords and cord sets, Interpower follows North American and international standards, along with minimum and maximum lengths per country regulations and/or standards,” according to Barnett. It should be noted that application limits need to be considered. For example, cords over 50 feet in the United States and Canada will have the amperage rating derated (the longer the cord, the lower the voltage due to resistance and cord diameter). For international applications, the derating depends on the application and the cable used in the assembly. For information on the cord set configurations allowed, see the International Cord Set Configurations chart and the North American Cord Set Configurations chart.

Interpower uses a standard method of measurement for measuring all power cords and cord sets. This measurement is from the face of the connector or plug, not including the pins, to the end of the cable, stripped or not.

Methods of measurements are included in the following standards: UL 817, CSA 22.2 no. 21-14, and IEC 60799.

Tested & Retested

Interpower manufactures power cords and cord sets for multiple countries and regions. “Cords that are manufactured by Interpower are 100% tested,” Barnett explained. “The production electrical testing includes Hipot, continuity, and pull. One Hipot test checks for shorts between the ground and line and the ground and neutral. A second Hipot test checks for shorts between the line and neutral wires. The purpose of the continuity test is to confirm the assembly is wired correctly and there are no breaks in the wire from one end to the other. The pull test ensures that a quality crimp exists.” All plugs, connectors, and cable are also visually inspected for surface quality, molding flash, and markings.